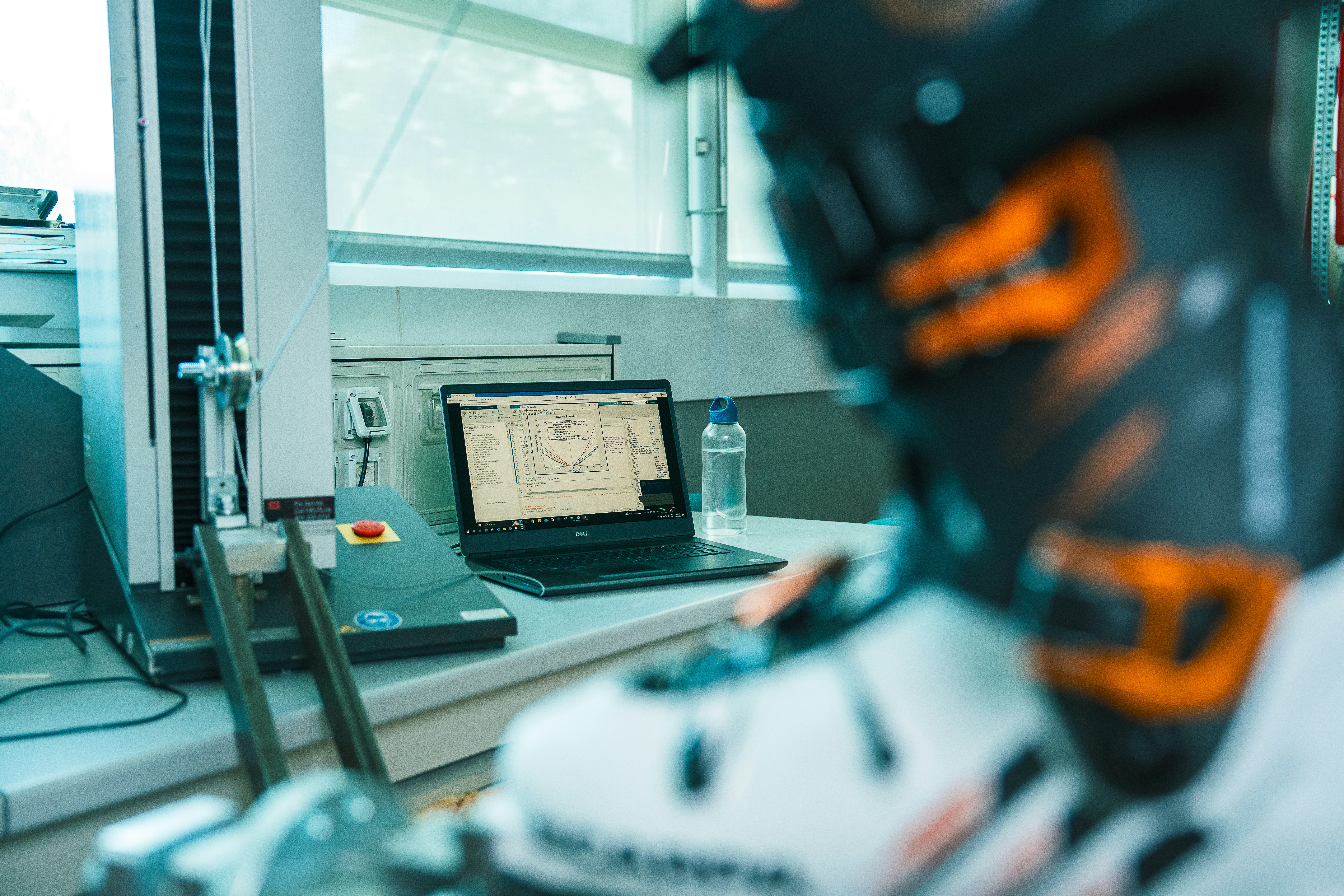

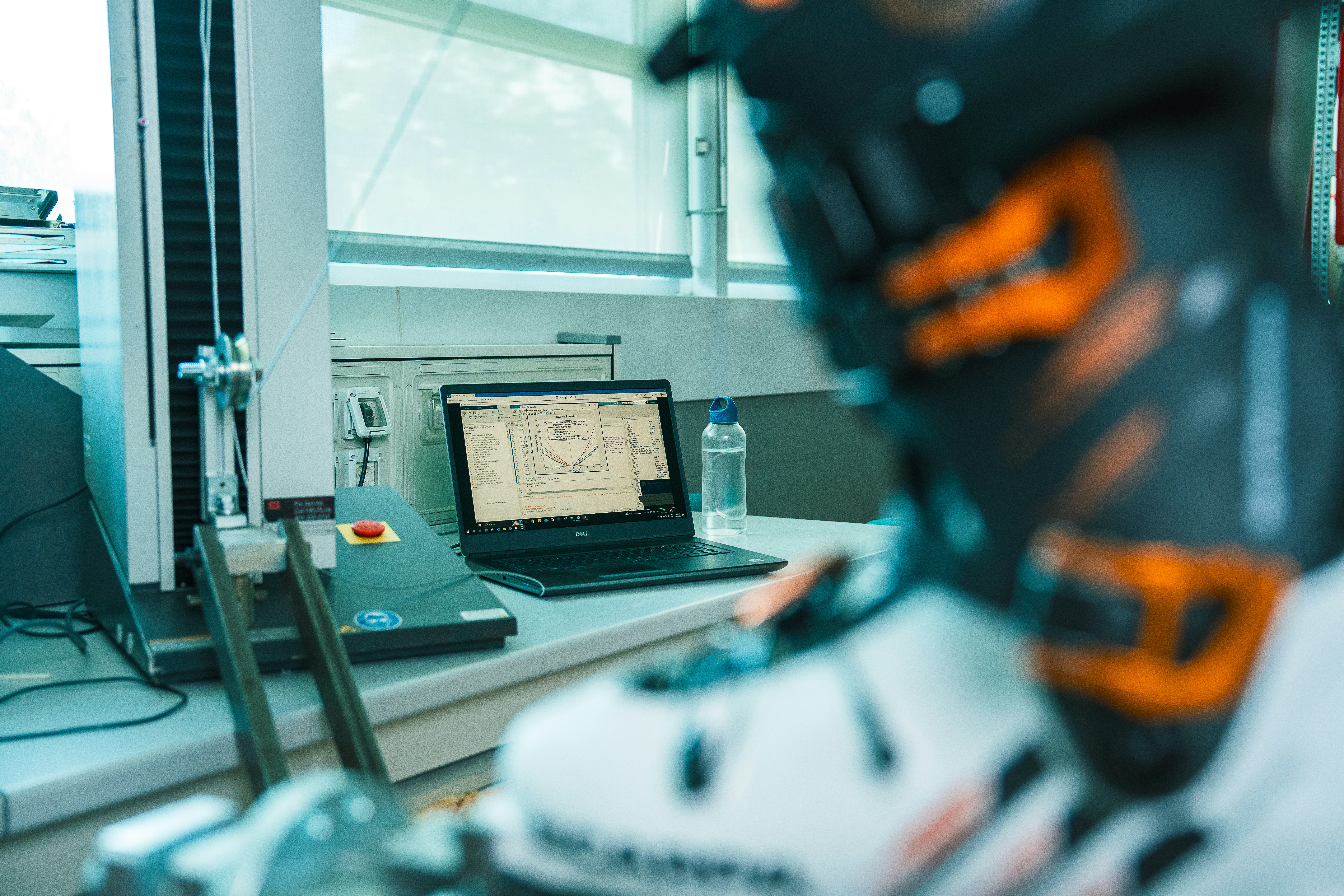

Boots under the microscope

We tested flex, walkability and liner warmth in the Light, Tour and Free unisex models

- Author: Martino Colonna

- Photographer: Giovanni Danieli

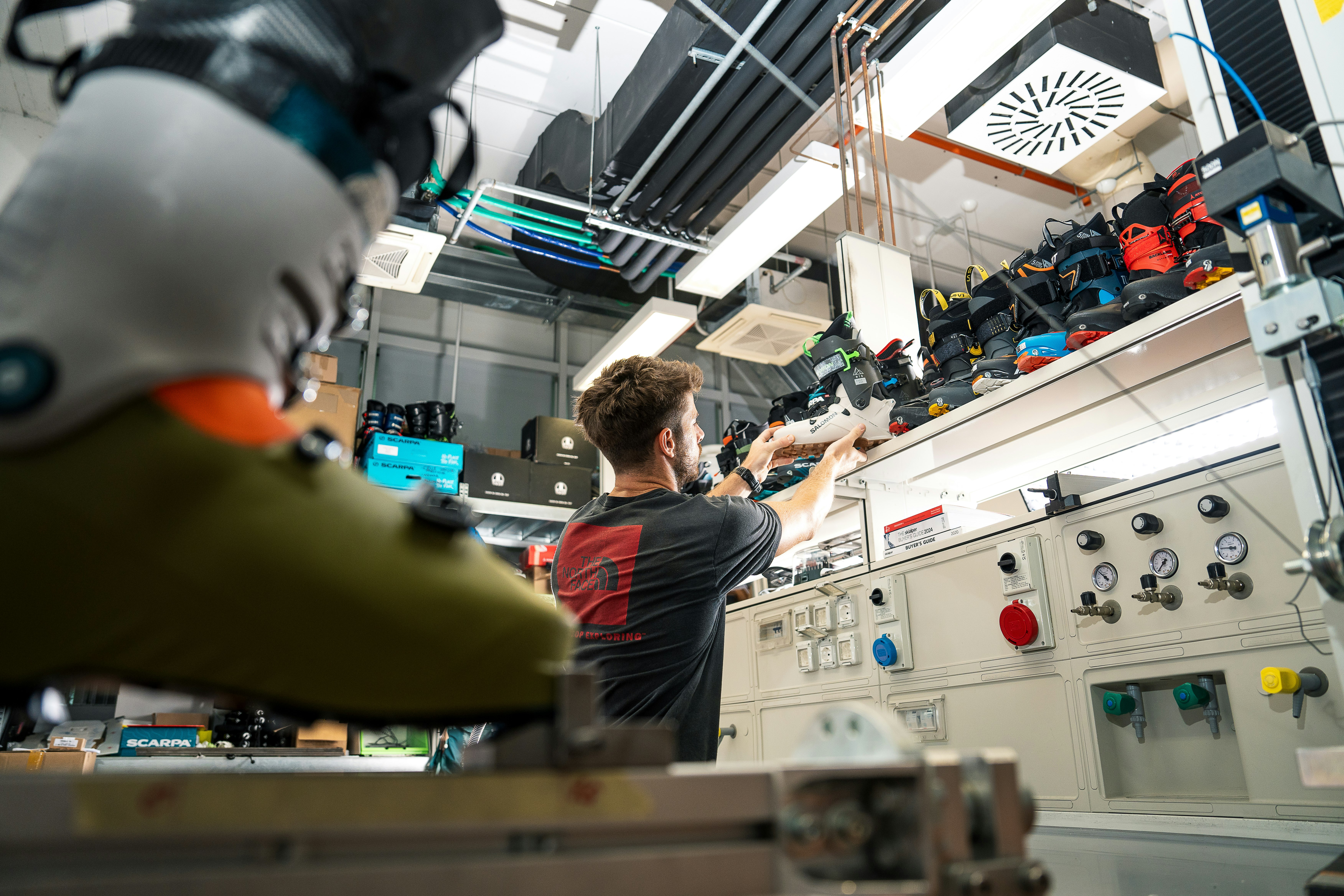

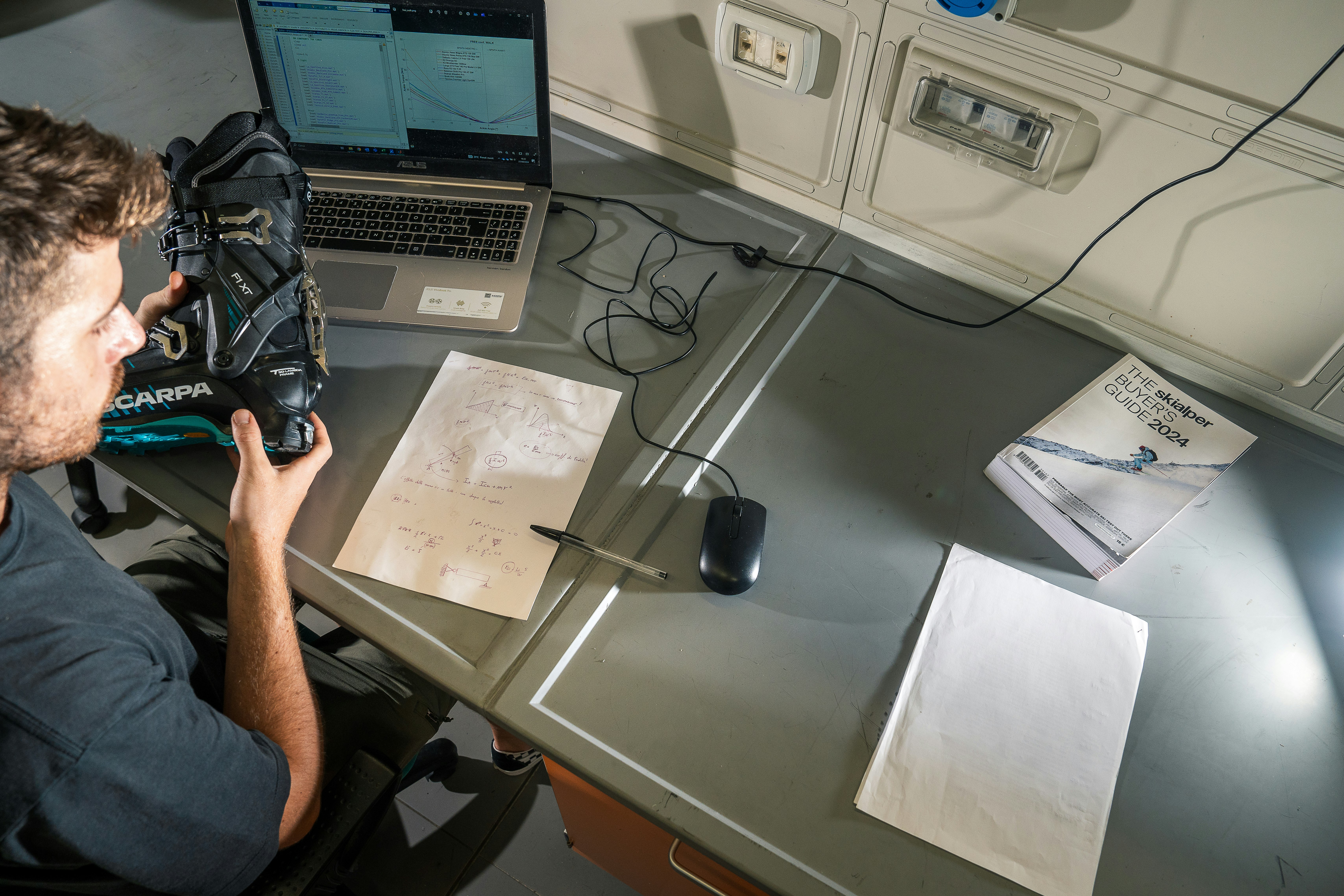

For the third year running, in collaboration with the University of Bologna, we carried out lab tests to measure boot flex at four different angles, walkability to the fore and aft, and the thermal insulation of the liners. Each model was then assessed in terms of sustainability.

We used exactly the same setup as last year to ensure the tests were comparable. Nevertheless, the relative data for each category use this year’s best product in the category as a benchmark. As they may be different from the previous year, the relative values for carry-over models may vary slightly compared to last year.

Flex testing

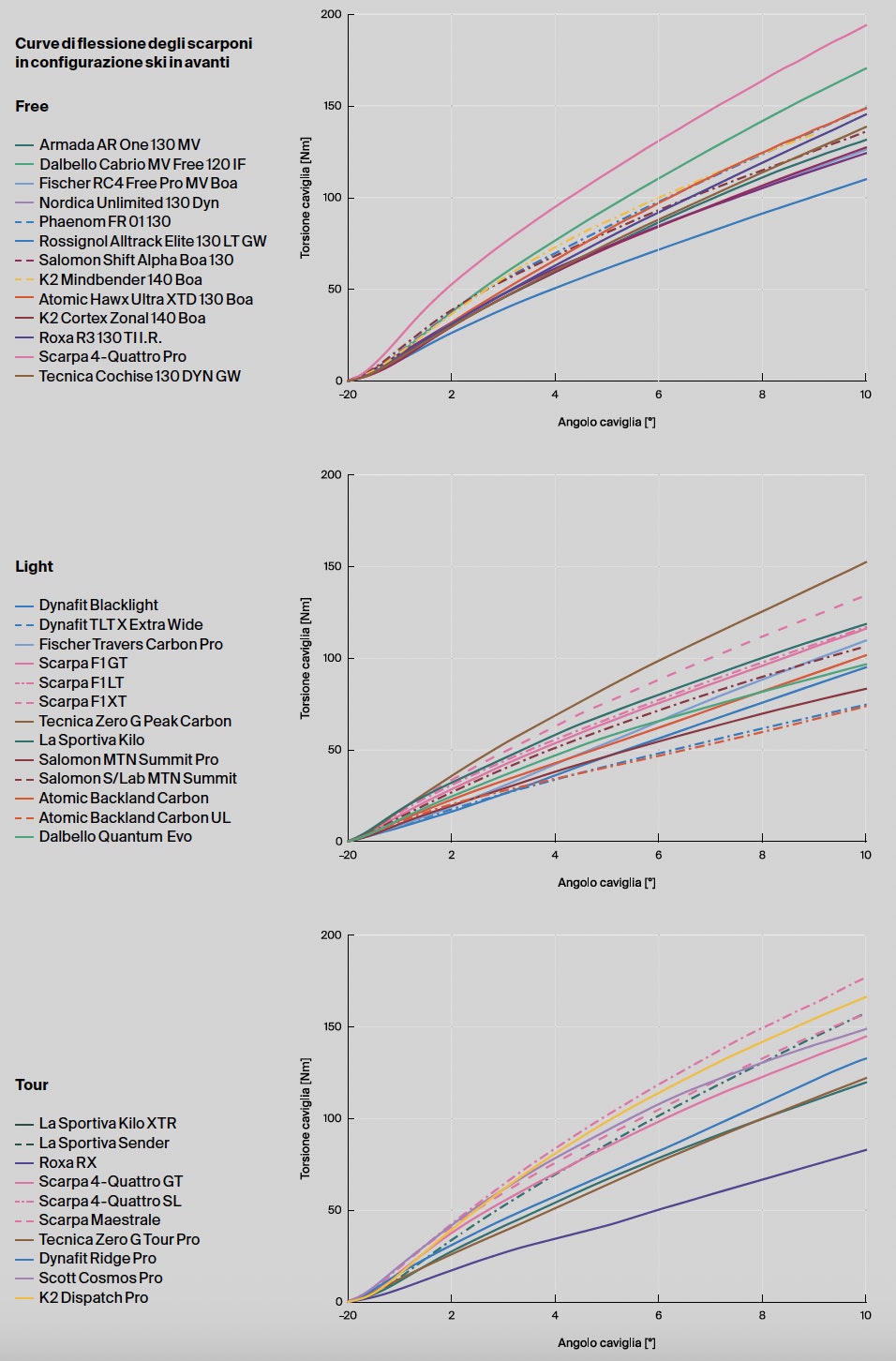

As in previous years, the flex was measured at four angles (fore and aft, at both 45° and 90°) to provide information across all usage areas of the boot in descent. The test procedure, force applied, buckle closure and temperature all remained unchanged from previous years. And they were carried out using the same prosthesis and friction-free articulated ankle that were used in past tests. For each category, we’ve rationalized the flex data by giving a value of 10 to the boot with the highest stiffness index at 10° of flex (for the forward 45° and 90° flex tests), and 4° for the rear flex test. All data can be viewed in the graphs published in the online version of the Buyer’s Guide. The shape of the curve indicates how progressive, regressive or linear the boot's flex is.

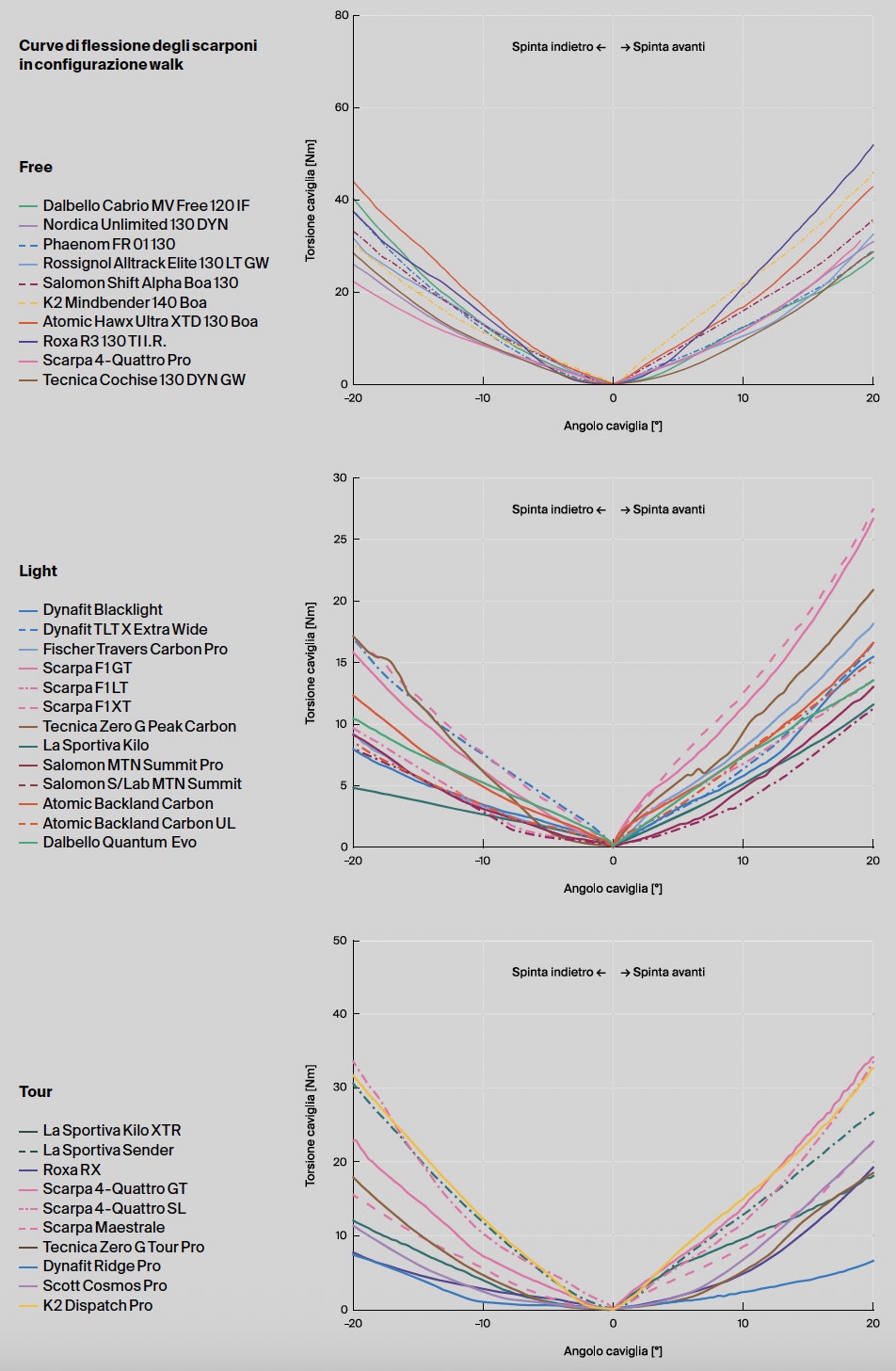

Walkability testing

The walk tests were carried out in the same way as previous years: by putting the ski/walk mechanism in walk mode and fastening the buckles in the ladder according to manufacturer recommendations. Velcro straps, where present, were left completely undone. As with the flex tests, the boot was held firmly in place so as to isolate and measure the movement of the cuff relative to the shell. The data were recorded as the torque (in Nm) required to reach an angle of 20 degrees to the fore and aft. The complete curves clearly demonstrate the force required to rotate the cuff as a function of the angle of rotation. In practice, you almost never reach a fore or aft angle of 20 degrees when walking. For example, some boots rotate easily up to 15 degrees, then become stiffer beyond this angle. Yet, generally speaking, they perform just as well in ascent as models with much lower values at 20 degrees. In the Freeride category, three models (the K2 Cortex Zonal 140 BOA, Fischer RC4 Free Pro MV BOA, and Armada AR One 130 MV) don’t have a ski/walk mechanism and for this reason weren’t tested for walkability.

Thermal insulation testing

The thermal testing of the liners was carried out using the same procedure as previous years. Specifically, heat dissipation was measured with a temperature gradient of 37°C (98.8°F) between the interior and exterior to simulate wear with an external air temperature of 0°C. Based on the results of the insulation testing, which is similar to that used for evaluating insulation classes for buildings, we’ve created a linear thermal efficiency scale using a lettered rating system, where class A provides the best insulation and class F the worst. The temperature was measured after five minutes and averaged over the fore and aft sections of the liner. To determine class A we used the boot with the highest thermal insulation among those tested, while class F was established using the hypothetical situation whereby the temperature of the liner reached 35 degrees (95°F, fortunately not registered in any of the boots tested).

Sustainability testing

The boots were evaluated based on the following criteria:

- the presence of material from renewable sources (non-biodegradable) in the shell and cuff;

- the presence of recycled material;

- the possibility of disassembly for potential recycling.

When looking at designs for recycling, we attempted to dismantle each boot into its component parts (shell, cuff, buckles and other hardware) using screwdrivers alone. We penalized the use of rivets for attaching the cuff to the shell and for securing the buckles. Parts molded using materials with different physical compositions (bi-injections and over-molding) and glued components were also marked down. The use of rivets prevents parts being replaced if they break, making it necessary to replace the entire boot.

Flex: Free vs Tour

The results of the flex tests show that the Freeride category has the stiffest forward flex overall, with an average of 140 Nm at 10°; closely followed by Tour, with an average of 135 Nm; then Light, with an average of 105 Nm.

The results were very similar to last year’s, indicating that Tour and Freeride boots are very close in terms of forward stiffness. It should, however, be noted that unlike Light boots where both cuff and shell are always made from a polyamide-based material, Tour boots (like the Scarpa 4-Quattro GT with cuff and shell in TPU), as well as some Freeride models, are made from polyolefin components (like the cuff of the Salomon Shift Pro) or from TPU (like the cuff and shell of the K2 Cortex Zonal 140 BOA and Armada AR One 130 MV). These materials are more temperature sensitive, as their stiffness increases as the temperature drops, so it’s conceivable that at 0°C (32°F) they are just as stiff, if not stiffer, than boots made completely from polyamide. In the Tour category, the stiffest models in all four directions were the Scarpa 4-Quattro SL, followed by the La Sportiva Sender, the Scarpa Maestrale and the K2 Dispatch Pro. In the Light category, the stiffest model, like last year, was the Scarpa F1 XT, followed by its slightly softer sibling the F1 GT, and the Tecnica Zero G Peak. In the Freeride category, the stiffest models in all four directions were the Scarpa 4-Quattro Pro and Dalbello Cabrio MV Free 120 IF, especially in the first part of the curve. In these models the tongue immediately provides strong support resulting in a regressive flex, compared to the overlap construction of other boots with a more linear flex pattern. Other cabrio boots also proved to be stiffer laterally and to the rear (like the Armada AR One 130 MV, despite being made from TPU which is more sensitive to variations in temperature). It’s important to note, however, that almost all Freeride overlap boots have either a shell or cuff made from TPU or polyolefin, which is less stiff at the temperature at which the tests were carried out. Plus, there are new, more rigid TPUs on the market whose performance is less influenced by temperature than the traditional TPUs used in alpine race boots. Since we don’t have information on what type of TPU was used, we can’t draw any conclusions on this aspect.

Walkability: Tour better than Free, despite similar stiffness

As for the walkability tests, we can see a clear difference between the Light (with an average of 17 Nm to the fore and 12 Nm to the aft, almost identical to last year), Tour (24 Nm and 19 Nm respectively, also practically identical to last year), and Freeride (35 Nm and 33 Nm respectively, not including the three models without ski/walk mechanism) models.

In other words, Tour boots offer better walkability than Freeride boots despite their similar stiffness on the downhill. The best Freeride boots in terms of walkability were the Dalbello Cabrio MV Free 120 IF to the fore, and the Scarpa 4-Quattro Pro to the aft, with results close to those of the Tour category. And in that category the clear winner is the Dynafit Ridge which scored some incredible results (7 Nm fore, 7 Nm aft), comparable to the Light category, where the top result went to the La Sportiva Kilo, followed by the Dynafit Blacklight and the two Salomon MTNs.

Warmth: Free comes out on top

The thermal testing results showed how heavier Freeride boots have, on average, better thermal insulation in their liners—all class A or A/B. In the Tour category, four models were classed as cat A, five as cat A/B, and two in cat B. In the Light category, all boots were classed as cat B, except the Dynafit TLT X (cat C), and the Dynafit Blacklight (cat B/C).

Sustainability: recycled materials found only in the soles

As for sustainability, we found that none of the boots tested contained recycled material in the cuff or shell, and only two had any in the sole (the Salomon MTN models). The number of boots that use materials from natural sources remains around the same as last year, after a sharp rise two years ago. Tour boots were found to use the most sustainably-sourced materials, with six out of ten models containing materials from renewable sources. Here we’re mainly talking about Pebax RNW and Grilamid Bio (made from castor oil), as well as TPU in the Scarpa 4-Quattro GT. It’s important to emphasize that the use of naturally-sourced raw materials doesn’t change the material’s mechanical properties and durability, nor does it mean that it’s biodegradable.

Share this article